Composite Suspension Insulator

Composite Suspension Insulator is also known as "composite long rod insulator". The term "long rod" is actually used for a specific design of porcelain insulator which was first introduced in Germany in the 1920s as an alternative to cap-and-pin insulators (and also for critical ambient conditions, for example high pollution). The construction of a composite long rod is shown in Fig.2.1. The fiber reinforced core, the metal fittings and the silicone housing can be seen.  Fig. 2.1 Construction of a composite long rod insulator

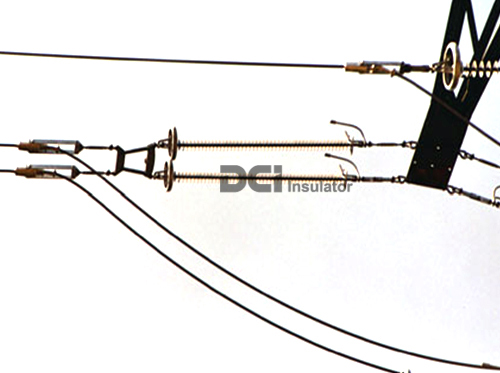

Composite long rod insulators benefit from the manufacturing possibilities of the FRP (fibre reinforced plastic) rod, and in particular from the fact that FRP rods can be produced practically endlessly in one piece in lengths up to 20m which is impossible with conventional insulator materials such as porcelain and glass. Composite long rod insulators are currently produced in lengths of 10–100 cm for low-voltage and medium-voltage network systems, and in lengths up to 10m and more for today’s UHV network systems (Figs. 2.2 and 2.3).  Fig. 2.2 Suspension string  Fig. 2.3 Tension string

|