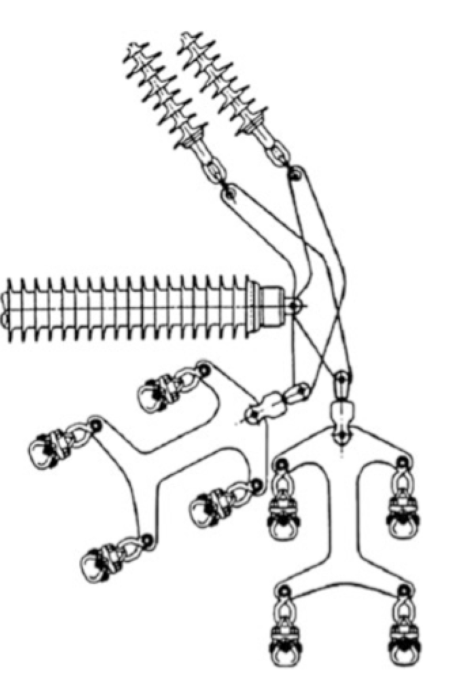

As it becomes increasingly difficult to obtain approval for new transmission channels, various new line upgrade technologies have been developed and are being implemented.The basic idea is to use existing line corridors to transmit more electricity.One possible option is to use high temperature low sag (HTLS) conductors to increase the current and/or modify the top geometry to increase the voltage.For the latter, composite insulators provide a new option.These characteristics made possible the design of HV insulated crossarms.This replaces the existing steel lattice wishbone and provides the additional ground clearance required to increase line voltage.

The advantage of a composite insulator in an insulated wishbone over an insulator made of porcelain or glass is that, in such a wishbone, the stanchion is pressurized.This can be maintained only by using composite insulators with appropriate cross sections, especially for high voltages (i.e., longer insulator lengths).In addition, composite insulators have high flexural strength.It has elastic limit in its ultimate strength and non-brittleness.All of this becomes important when the insulator is pressurized.But there are still some problems to be solved.For example, under strong crosswind, the stability of the line segment with insulated crosswind and the wire tension on adjacent spans are not equal.In each case, the right solution requires an in-depth understanding of the problem and the appropriate software tools.Another issue requiring special attention is the eccentric application of compression loads to the struts.This will cause it to over-bend and reduce its carrying capacity. A good engineering solution is to design a conductor attachment so that the load is always on the axis of the pillar.

In practice, friction at many joints of the transverse arm must also be considered.Because it can have a significant impact on the mechanical properties of the crossarm.This can only be reasonably reproduced by numerical simulation using the finite element method (FEM).On the other hand, due to the above uncertainties,Comprehensive mechanical testing of the insulated wishbone is recommended,In addition, the insulators (posts and posts) shall be type tested in accordance with various IEC regulations.Standard.In particular, the insulated wishbone should be able to withstand the maximum allowable load without permanent deformation or other damage.This shall be verified by the procedure described in IEC standard 61952, Section 6.3.1, i.e., by 96 hours of application, the maximum allowable load of the structure is increased by a safety margin of 10%.Upon completion of the test, composite post insulators shall be cut and inspected in accordance with the method described in IEC 61952.The objective is to inspect the interior near and between the two parts for damage.Rod, especially the point at which maximum deflection is observed during testing.Insulated crossarms with composite insulators are the only practical solution for upgrading existing high-voltage lines without requiring extensive modifications to the support structure.However, the application still requires complex design skills, manufacturing experience, and comprehensive testing to verify the long-term reliability of the concept.

From:https://www.inmr.com/line-uprating-composite-insulators/